Start Your Welding Career in the Netherlands – Training Opportunities Await!

Understanding the Basics of Welding

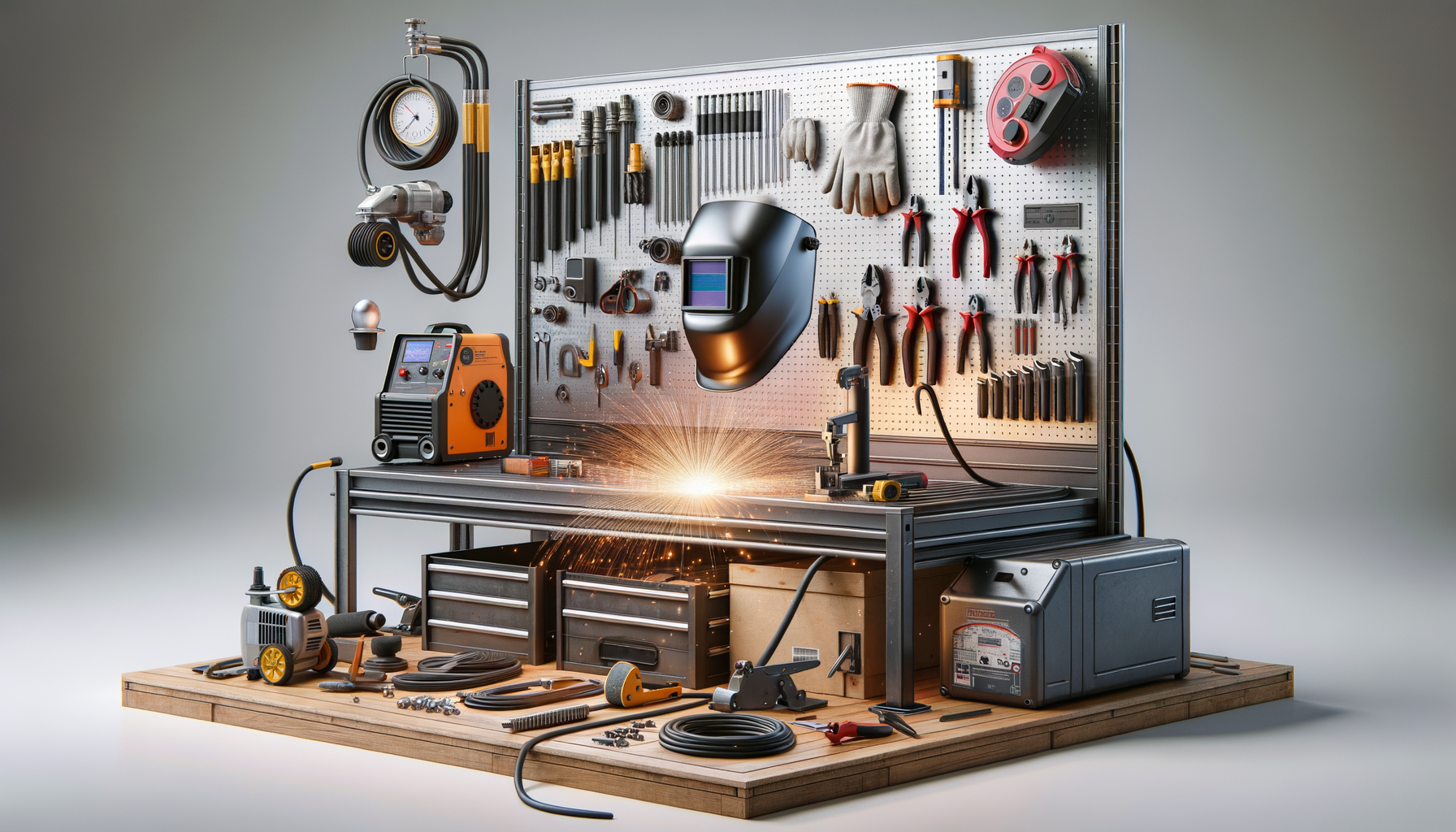

Welding is a foundational skill in many industries, playing a crucial role in the construction, automotive, and manufacturing sectors. At its core, welding involves the joining of materials, typically metals or thermoplastics, through high heat to melt the parts together. Once cooled, the materials form a strong joint. This process is not just about fusing metals; it’s an art that requires precision, skill, and a deep understanding of materials and techniques.

There are several types of welding, each with its unique applications and requirements. The most common types include:

- MIG (Metal Inert Gas) Welding: Known for its speed and versatility, MIG welding is often used in automotive and construction industries.

- TIG (Tungsten Inert Gas) Welding: This method is known for its precision and is often used in aerospace and artistic applications.

- Stick Welding: A traditional method that’s still widely used in construction and repair work due to its simplicity and effectiveness.

Each of these methods requires specific training and practice. Understanding the right technique for the right material is crucial for creating durable and safe welds. The choice of method often depends on factors such as the type of material, the thickness of the workpieces, and the required strength of the joint.

Welding is more than just a technical skill; it’s a blend of science and art. Welders must understand the properties of different metals and how they interact under heat. This knowledge helps them adjust their techniques to produce the best results. Moreover, welders often need to work in diverse environments, from small workshops to large construction sites, requiring adaptability and problem-solving skills.

The Path to Becoming a Skilled Welder

Embarking on a career in welding requires a mix of formal education and hands-on experience. Many aspiring welders start their journey by enrolling in vocational schools or community colleges that offer specialized welding programs. These programs typically cover the fundamentals of welding, including safety protocols, equipment handling, and basic techniques.

One of the key components of welding training is understanding and adhering to safety standards. Welding involves working with high temperatures and potentially hazardous materials, making safety a top priority. Training programs emphasize the importance of protective gear, such as helmets, gloves, and aprons, to safeguard against burns and eye damage.

After completing formal education, gaining practical experience is crucial. Many welders begin as apprentices, working under the guidance of experienced professionals. This on-the-job training allows them to apply their classroom knowledge in real-world scenarios, honing their skills and building confidence.

Certification is another important step in a welder’s career path. Various organizations offer certification programs that validate a welder’s skills and knowledge. These certifications can enhance job prospects and open doors to more advanced positions. In the Netherlands, for example, certifications can be obtained through recognized bodies, ensuring that welders meet industry standards.

Continuing education is also vital in this field. As technology evolves, new welding techniques and equipment are developed. Welders who stay updated on these advancements can improve their efficiency and expand their skill set, making them more valuable to employers.

Opportunities and Challenges in the Welding Industry

The welding industry offers a plethora of opportunities for those willing to invest time and effort into mastering the craft. In the Netherlands, the demand for skilled welders is on the rise, driven by the country’s robust construction and manufacturing sectors. This demand translates into a steady job market with competitive salaries and benefits.

One of the appealing aspects of a welding career is the diversity of job opportunities. Welders can find employment in various industries, including:

- Construction: Involved in building infrastructure, from bridges to skyscrapers.

- Automotive: Engaged in manufacturing and repairing vehicles.

- Aerospace: Contributing to the production and maintenance of aircraft.

- Shipbuilding: Playing a vital role in constructing and repairing ships.

Despite the promising opportunities, the welding industry also presents challenges. The physical demands of the job can be significant, requiring strength and stamina. Welders often work in challenging environments, such as confined spaces or at heights, which necessitates a high level of physical fitness and mental resilience.

Moreover, the industry is continually evolving with technological advancements. Automation and robotics are becoming increasingly prevalent, changing the landscape of welding jobs. While this can lead to more efficient processes, it also requires welders to adapt and learn new skills to remain relevant in the workforce.

In conclusion, a career in welding offers a rewarding path for those interested in hands-on work and skilled trades. With the right training and a commitment to continuous learning, individuals can find success and fulfillment in this dynamic field. Whether you’re just starting or looking to advance your career, the welding industry in the Netherlands holds promising potential for growth and development.