Industrial Manufacturing Jobs in the U.S.: Start with Training

The Importance of Industrial Manufacturing Training

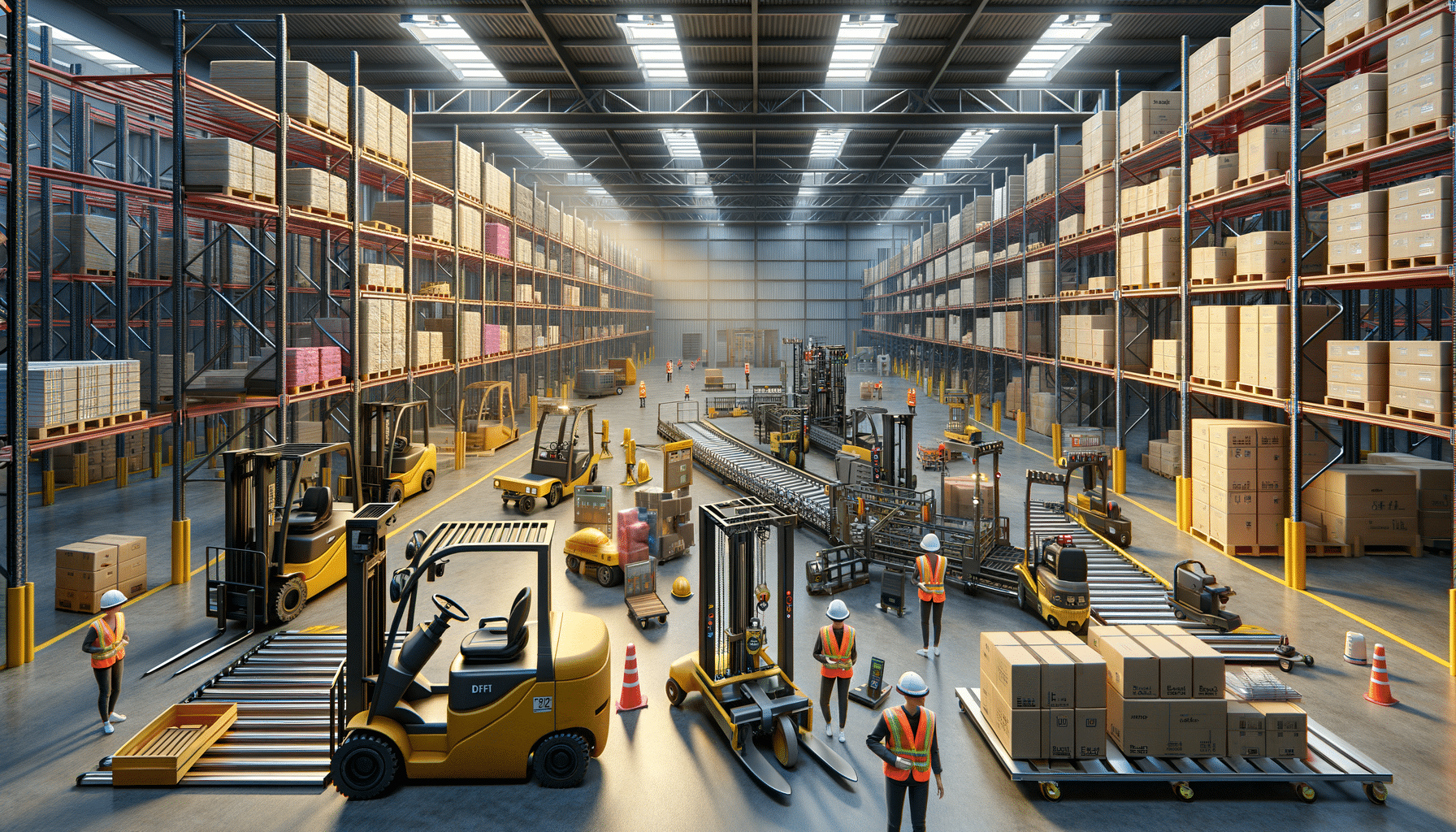

Industrial manufacturing is a cornerstone of the U.S. economy, contributing significantly to GDP and employment. As the industry evolves with technological advancements, the need for skilled workers has never been more critical. Training in industrial manufacturing equips individuals with the necessary skills to operate complex machinery, understand production processes, and maintain high standards of quality and safety.

Training programs often cover a wide range of topics, including:

- Machine operation and maintenance

- Quality control techniques

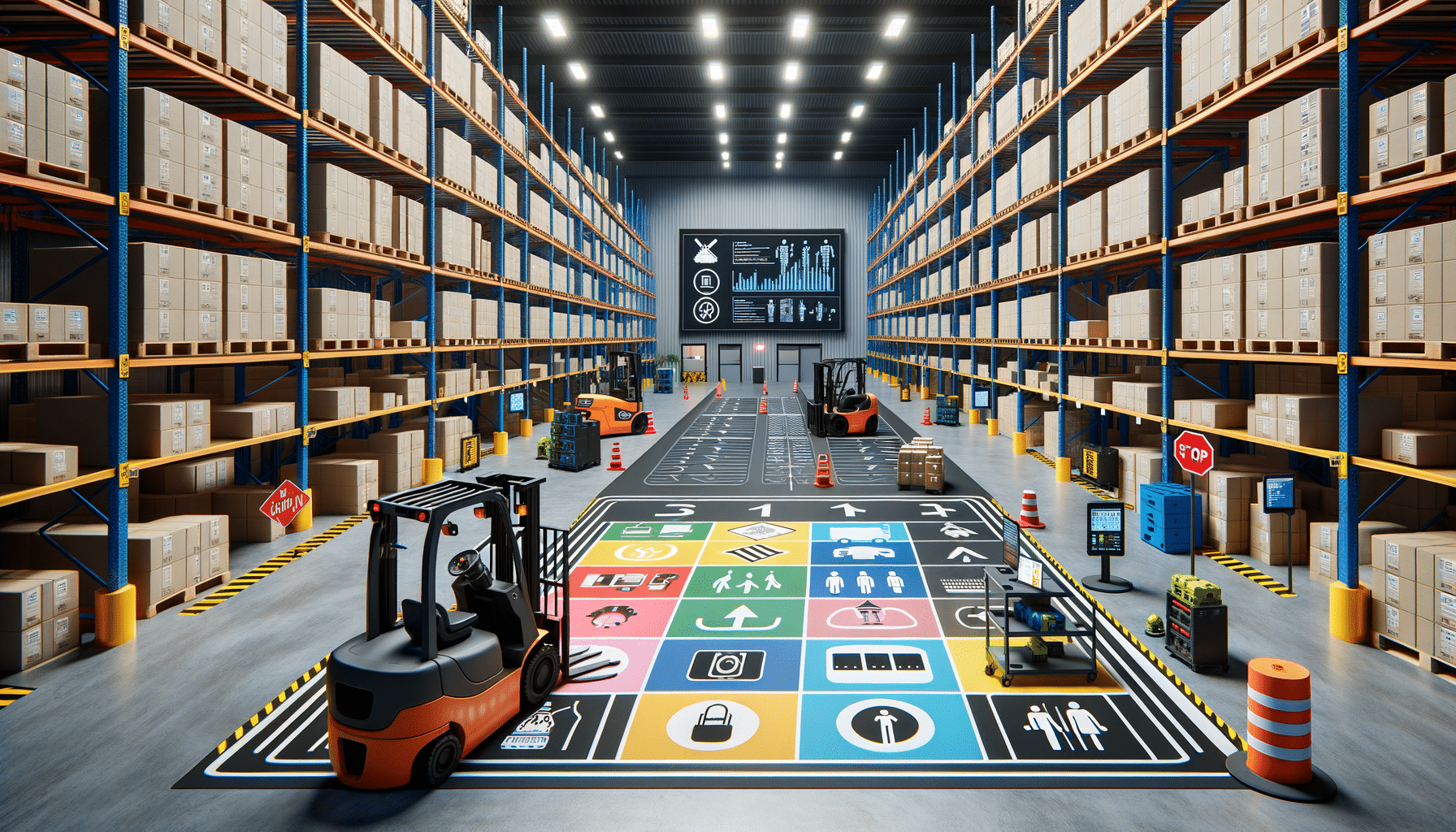

- Safety protocols

- Lean manufacturing principles

By investing in training, companies not only improve productivity but also ensure the safety and well-being of their workforce. Trained employees are more efficient, make fewer errors, and are better equipped to handle the demands of modern manufacturing environments.

Types of Training Programs Available

There are various training programs available for those interested in industrial manufacturing. These programs range from short-term certifications to comprehensive degree courses, each designed to cater to different career goals and time commitments. Some popular types of training include:

- Apprenticeships: These combine on-the-job training with classroom instruction, allowing participants to earn while they learn.

- Technical Certifications: Short-term programs focusing on specific skills, such as CNC machining or welding.

- Associate Degrees: Two-year programs that offer a more in-depth understanding of manufacturing processes and technologies.

- Continuing Education: Workshops and seminars for current professionals looking to update their skills.

Each of these programs provides unique benefits and can be tailored to meet the needs of both newcomers and seasoned professionals. By choosing the right training path, individuals can enhance their career prospects and contribute effectively to the manufacturing sector.

Challenges and Opportunities in Industrial Manufacturing Training

While industrial manufacturing training offers numerous benefits, there are also challenges to consider. One of the primary challenges is keeping the curriculum up-to-date with the latest technological advancements. As automation and digitalization continue to transform the industry, training programs must adapt to include new skills and knowledge areas.

Another challenge is accessibility. Not all potential workers have easy access to training facilities or programs, particularly in rural areas. Addressing this issue requires collaboration between industry leaders, educational institutions, and government bodies to provide more inclusive and widespread training opportunities.

Despite these challenges, there are significant opportunities for growth and innovation in industrial manufacturing training. Online learning platforms and virtual reality simulations are emerging as effective tools for delivering training remotely and interactively. These technologies can make training more accessible and engaging, ultimately preparing a more skilled workforce for the future of manufacturing.