Understanding the Basics of Welding Training

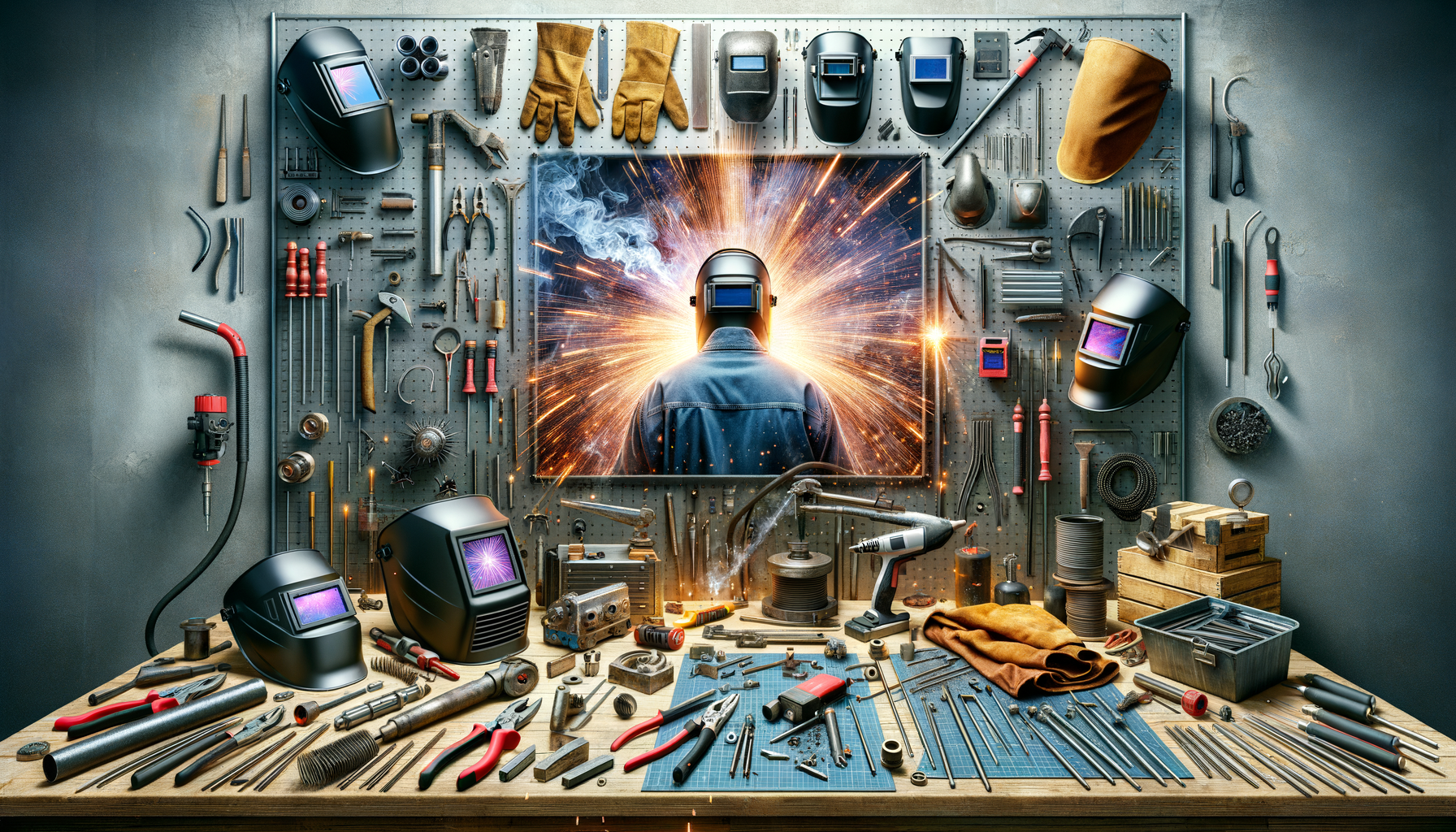

Welding is a skill that combines precision, technique, and an understanding of materials. For anyone considering a career in this field, understanding the basics of welding training is crucial. Welding training programs are designed to equip individuals with the necessary skills to join metal parts together using heat and pressure. These programs vary in length and complexity, often starting with foundational courses that cover safety protocols, basic welding techniques, and the use of welding equipment. The importance of safety cannot be overstated in welding training. Proper safety training ensures that welders are aware of the potential hazards and know how to protect themselves and others. This includes learning about protective gear, understanding the risks of exposure to harmful fumes, and knowing how to handle equipment safely.

Welding training also involves hands-on practice, which is essential for mastering the skill. Trainees learn to work with different types of metals, such as steel, aluminum, and stainless steel, each requiring specific techniques and tools. The training often includes instruction on various welding methods, such as MIG, TIG, and stick welding, each suited to different applications and materials. By the end of a basic training program, individuals should be able to perform simple welding tasks and understand the principles behind more complex techniques.

Advanced Welding Techniques and Specializations

After mastering the basics, welders can choose to specialize in advanced techniques that can open doors to more opportunities and higher pay. Advanced welding training programs delve into specialized techniques and applications, such as underwater welding, aerospace welding, and robotic welding. These specializations require additional training and certification, as they involve more complex processes and often work in challenging environments.

For instance, underwater welding is a highly specialized field that combines commercial diving skills with welding expertise. It is used in the maintenance and construction of underwater structures, such as pipelines and offshore oil rigs. This type of welding requires knowledge of diving physics, hyperbaric welding techniques, and the ability to work in low-visibility conditions. Similarly, aerospace welding involves working with high-strength materials and precision techniques to ensure the safety and integrity of aircraft components. This specialization demands a deep understanding of metallurgy and the ability to work with strict quality standards.

Robotic welding, another advanced area, involves programming and operating welding robots used in manufacturing. This field requires knowledge of automation, robotics, and computer programming, making it a suitable choice for those interested in technology and innovation. By pursuing advanced welding techniques and specializations, welders can enhance their skills and increase their employability in various industries.

Choosing the Right Welding Training Program

With numerous welding training programs available, choosing the right one can be daunting. Prospective welders should consider several factors when selecting a program, such as accreditation, curriculum, facilities, and instructors’ expertise. Accreditation ensures that the program meets industry standards and provides quality education. It’s essential to choose a program that is recognized by professional organizations and employers.

The curriculum should cover a comprehensive range of topics, from basic welding techniques to advanced specializations. Look for programs that offer hands-on training and access to modern equipment, as practical experience is crucial for developing proficiency. Facilities should be well-equipped with the latest tools and safety gear, providing a realistic training environment.

Instructors play a vital role in the learning process, so it’s important to choose a program with experienced and knowledgeable instructors. They should have industry experience and be able to provide guidance and mentorship to students. Additionally, consider programs that offer job placement assistance or apprenticeships, as these can provide valuable opportunities to gain real-world experience and connect with potential employers. By carefully evaluating these factors, individuals can choose a welding training program that aligns with their career goals and sets them on the path to success.